An Italian company with a global outlook.

A company well-known for its flexibility and expertise.

A group united by a passion for precision.

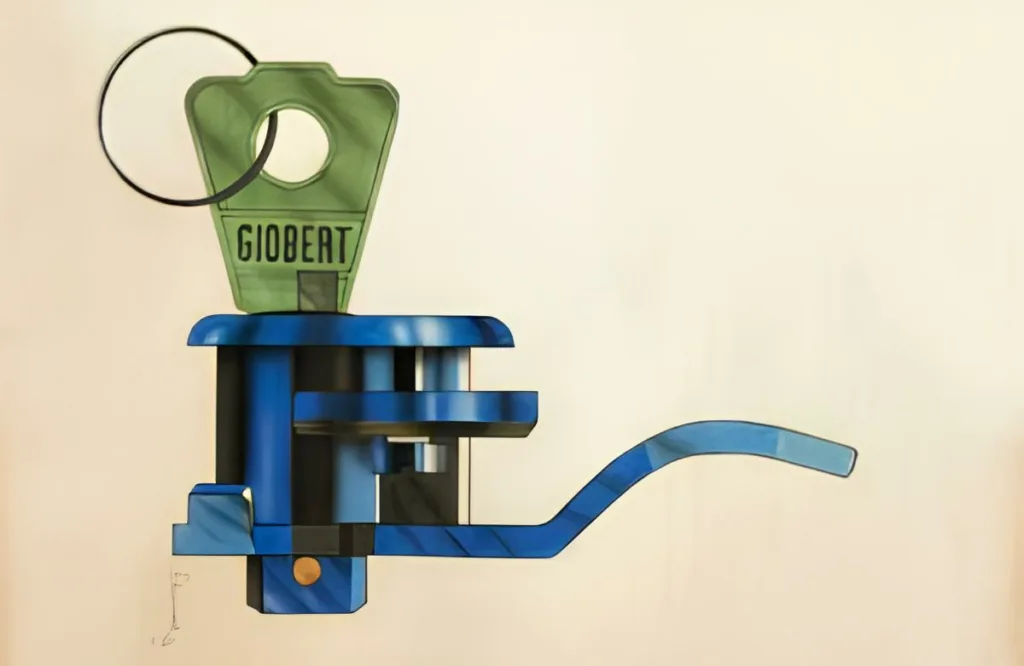

Giobert supplies to the automotive industry keys, lock cylinders and interior components for more than 60 years.

The company is both a Tier 1 supplier and a customer partner, and due to its approach flexibility, it is possible to supply from big volumes to small specific and premium products.

Its products are applied on famous Italian and international brands, including Fiat, Alfa Romeo, Lancia, Maserati, Ford, Iveco, BMW Motorrad and Piaggio.

Founded in Turin in 1953, Giobert is an international group with five plants: two in Italy, one in Poland, one in Brazil and newest in Albania, employing an amount of 350 people.

The company has always managed the entire process, from design and development to production, to delivery the finished goods.

There was an achievement of 34 million euros on its revenue in 2018.

1953-2023

Seventy years of growth.

In September 2023 Giobert celebrated its seventieth anniversary.

From its foundation to its expansion in Poland and Brazil, the company’s history is an enduring technical and technological growth curve marked by key products developed for leading car manufacturers.

At the age of 43 Giovanni Bertolino, a foreman in a company producing locks for cars, decided to become self-employed. Giobert came into being on September 2, in a small garage in Turin.

The first product was a new pin tumbler lock for the Vespa’s storage compartment supplied to mechanics. The key for the “Code 102” was the first marked Giobert on one side and Torino on the other.

The company became an S.p.A. and completed the handover from Giovanni to Emilio Bertolino, who became the majority shareholder and CEO.

The second plant in Rivoli

In the late 70s Giobert expanded, opening a second plant in Rivoli, where it gradually transferred its engineering and production of semi-finished products.

The launch of the Fiat Uno attested a major achievement for Giobert: the company became the official ‘Tier 1’ supplier for the full set of keys and lock cylinders (both ignition and doors) for a car.

Technological progress led to the introduction of an automated assembly line, meaning higher quality products and enabling automated testing.

In 1988 the Fiat Group adopted the Code W lock on all its models.

The first lock cylinders assembled on a fully automated production line, they offer even greater precision and security.

A decade of research culminated in patenting and producing a new family of key kits dubbed Code DE after the ‘desmodromic’ combination of tumblers and key.

The new products were used on the Lancia Lybra and then extended to all the Fiat Group’s product range. Code DE remains the standard in use today.

With the passing of Emilio Bertolino, his son Paolo took on the position of CEO and majority shareholder. Formerly director of engineering, the current chairman has been in the company since the 80s.

One of Emilio Bertolino’s last projects was to build a new company headquarters. The plant in via Pavia in Rivoli opened in 2005.

In order to be able to supply parts for the key 500, the company decided to open its first plant abroad.

Giobert Polska was the Group’s first international venture.

The start-up of the Gliwice plant was supervised by staff from the headquarters, who organised the new plant’s standards and processes based on those in Italy.

Autumn of 2011 saw the launch of Giobert do Brasil in Jaguariúna in São Paulo state, the country’s main industrial district. Since 2013 the plant has been supplying key kits and opening devices to FCA Group.

The plants in Brazil and Poland represent a change of scale and a great professional opportunity for the entire group.

The launch of the 4th site of the group, the 3rd out of Italy, keeps on and consolidate the multinational and multicultural Giobert vocations.

The Group’s headquarters are close to Turin, the automotive industry city. The two plants in Rivoli employ around 150 people.

Via Pavia

Strategic planning, Quality System Management, Laboratory, Human Resources, Purchasing, Manufacturing, Logistic

Corso Allamano

Sales, Product Design, Process Design, Manufacturing

Operative since 2007, the Polish plant in Silesia employs around 100 people, and its core activity is assembling products for clients in Eastern Europe.

Manufacturing / Customers direct support

Launched in 2019, this site employs around 60 people.

Manufacturing / Customers direct support

In 2011 Giobert opened its plant in the state of Saõ Paulo, Brazil’s most industrialised region. In this plant Giobert produces components and assemble finished products. The plant employs 50 people.

Manufacturing / Customers direct support

In Italy and on the plants abroad Giobert invests in order to keep the same precision and continuous improvement standards.

The group has adopted and applied in each site the Lean Manufacturing method: employees training and a better working environment, KAIZEN to eliminate unnecessary costs (MUDA), Just in Time on the logistics and the technic SMED for a precise stock management.

Among Giobert’s long-term customers there are Italy’s top car and motorcycle manufacturers, from Lancia and Piaggio in the 1950s to the established relationship with the FCA Group. It also works with some of the most famous international carmakers. Giobert’s customers includes:

On 2024 the amount of employees achieved the number of 410 people worldwide.